Description

Understanding Fiber Laser Cutting Machine Manufacturers

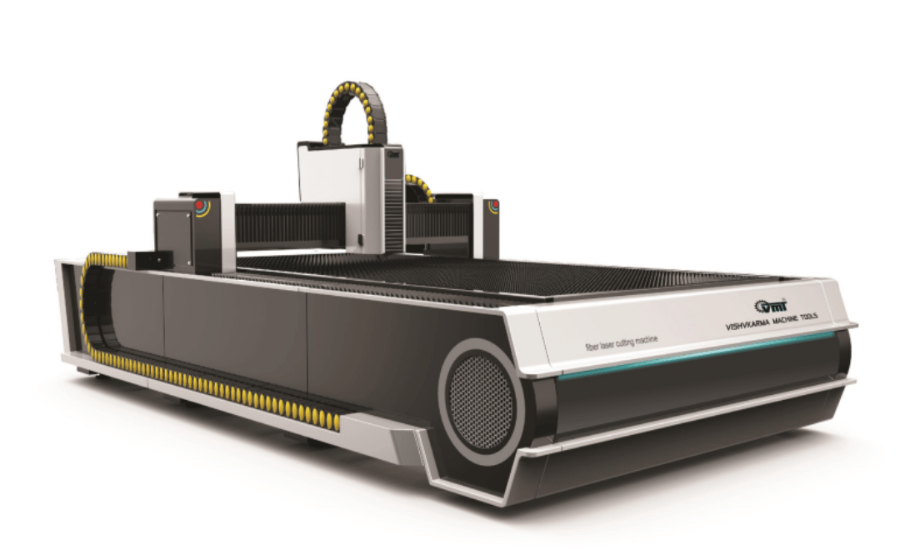

Fiber laser cutting machine Manufacturers have revolutionized industry with their precision, efficiency, and versatility. These machines utilize a fiber laser to cut through various materials, primarily metals, by focusing a high-powered laser beam onto the surface of the material. The laser’s energy melts, burns, or vaporizes the material, resulting in a clean and precise cut. Here’s a comprehensive look at the capabilities, advantages, and applications of fiber laser cutting machines.

How Fiber Laser Cutting Machine Manufacturers Work

A fiber laser cutting machine consists of several key components: the laser source, cutting head, motion system, cooling system, and control unit. The laser source generates the laser beam, which is then directed through optical fibers to the cutting head. The cutting head focuses the beam onto the material’s surface, where the intense energy density causes rapid heating and melting. Assist gases, such as oxygen or nitrogen, are often used to blow away molten material and enhance cutting efficiency and quality.

Advantages of Fiber Laser Cutting Machines

- Precision and Accuracy: Fiber laser cutting machines are renowned for their high precision and accuracy. They can achieve extremely fine cuts with tolerances as tight as a few micrometers. This level of precision is essential for industries requiring intricate and detailed components.

- Speed and Efficiency: These machines operate at high speeds, significantly reducing production time compared to traditional cutting methods. The high cutting speed, combined with the ability to process various materials without changing tools, boosts overall manufacturing efficiency.

- Versatility: Fiber laser cutting machines can cut a wide range of materials, including stainless steel, carbon steel, aluminum, brass, and copper. This versatility makes them ideal for various industries, from automotive and aerospace to electronics and medical devices.

- Cost-Effectiveness: Although the initial investment in a fiber laser cutting machine can be substantial, the long-term benefits often outweigh the costs. The machines have lower maintenance requirements, reduced consumable costs, and higher energy efficiency compared to CO2 lasers and other traditional cutting methods.

- Eco-Friendliness: Fiber lasers are more energy-efficient than other types of lasers, resulting in lower power consumption and reduced environmental impact. Additionally, the use of assist gases like nitrogen reduces the production of harmful byproducts.

Applications of Fiber Laser Cutting Machines

- Automotive Industry: Fiber laser cutting machines are used to manufacture various automotive components, including body panels, exhaust systems, and intricate parts that require high precision and consistency.

- Aerospace Industry: The aerospace industry benefits from fiber laser cutting technology for producing lightweight and durable components, such as turbine blades, structural parts, and intricate assemblies.

- Electronics Industry: In electronics manufacturing, fiber laser cutting machines are utilized to produce delicate and precise components, including circuit boards, connectors, and enclosures.

- Medical Device Manufacturing: The medical industry relies on fiber laser cutting for creating intricate and high-precision instruments, implants, and surgical tools that require biocompatibility and exacting standards.

- Signage and Advertising: Fiber laser cutting machines are employed in the production of signs, logos, and advertising materials, allowing for intricate designs and rapid production.

Future Trends and Innovations with Fiber Laser Cutting Machine Manufacturers

The future of fiber laser cutting technology looks promising, with continuous advancements enhancing performance, efficiency, and capabilities. Emerging trends include the integration of automation and artificial intelligence, which can further streamline operations and reduce human intervention. Innovations in beam quality and power levels are expected to expand the range of materials and thicknesses that can be efficiently processed.

Additionally, the development of compact and portable fiber laser cutting systems will make this technology more accessible to small and medium-sized enterprises, broadening its application scope.

Conclusion

Fiber laser cutting machines represent a significant advancement in manufacturing technology, helps unparalleled precision, speed, and versatility. Their ability to cut a wide range of materials with high efficiency and eco-friendliness makes them indispensable across various industries. As technology continues to evolve, fiber laser cutting machines are poised to play an increasingly vital role in modern manufacturing, driving innovation and productivity to new heights

| Model | VMT-S20/30/50 |

| Cutting Range | 3000-1500mm |

| Laser Power | 1000-6000W |

| Repositioning Accuracy | 0.02mm |

| Max. Moving Speed | 140m/min |