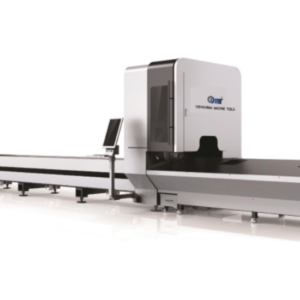

Top CNC router machine manufacturers provides spindle Italy 9.0kw air-cooling ATC

The Top CNC router machine manufacturers equipped with a 9.0kw Italy air-cooling ATC spindle is a cutting-edge solution designed for high-performance and precision in machining tasks. This advanced spindle helps significant power, enabling the machine to handle a wide range of materials with ease. The air-cooling system ensures that the spindle operates at optimal temperatures, even during extended periods of use, thereby enhancing its longevity and reliability.

One of the standout features of this CNC router is its Automatic Tool Changer (ATC) capability. The ATC allows for quick and efficient tool changes, minimizing downtime and maximizing productivity. With a 6-slot linear tool magazine, the machine can switch between different tools seamlessly, making it ideal for complex machining operations that require multiple tools.

The 9.0kw spindle operates at a high rotational speed, typically up to 24000rpm, which is crucial for achieving smooth finishes and precise cuts. This high-speed capability is particularly beneficial for tasks such as drilling, milling, and tapping, where accuracy and efficiency are paramount.

In addition to its impressive technical specifications, the CNC router is designed with user convenience in mind. The robust construction and high-quality components ensure durability and consistent performance, while the intuitive control interface simplifies operation, even for complex machining processes.

Overall, the CNC router with a 9.0kw Italy air-cooling ATC spindle represents a significant upgrade for any production environment, offering enhanced capabilities, efficiency, and precision to meet the demands of modern manufacturing

Key Features of Top CNC router machine manufacturers

- Versatility: CNC Routers can work with a wide range of materials, including wood, plastic, metal, and composites. They are used in industries such as woodworking, signage, aerospace, and prototyping.

- Precision: These machines provide high levels of precision and repeatability, ensuring consistent quality across multiple production runs.

- Automation: CNC Routers automate the cutting and shaping process, reducing labor costs and minimizing human error. This results in faster production times and improved efficiency.

- Customization: Users can create intricate designs and patterns using CAD software, allowing for customized products and prototypes.

- Ease of Use: Modern CNC routers come equipped with user-friendly interfaces and intuitive software, making them accessible to operators with varying levels of expertise.

Applications of Top CNC router machine manufacturers

Description on Top CNC router machine manufacturers